July 26, 2019

Computer graphics and 3D printing team presents findings at SIGGRAPH 2019

Researchers at world’s largest conference on computer graphics and animation

Two research groups from the Institute of Science and Technology Austria (IST Austria) will present their latest findings and collaborative efforts at SIGGRAPH 2019 – the world’s largest conference on visual computing, graphics and animation. The annual event brings together leading research groups and industry giants such as Marvel Studios, Disney and Pixar.

The multi-disciplinary team from both Professor Chris Wojtan and Professor Bernd Bickel’s research groups have a distinct focus on improving the modelling of fluids in animation and 3D printed molds.

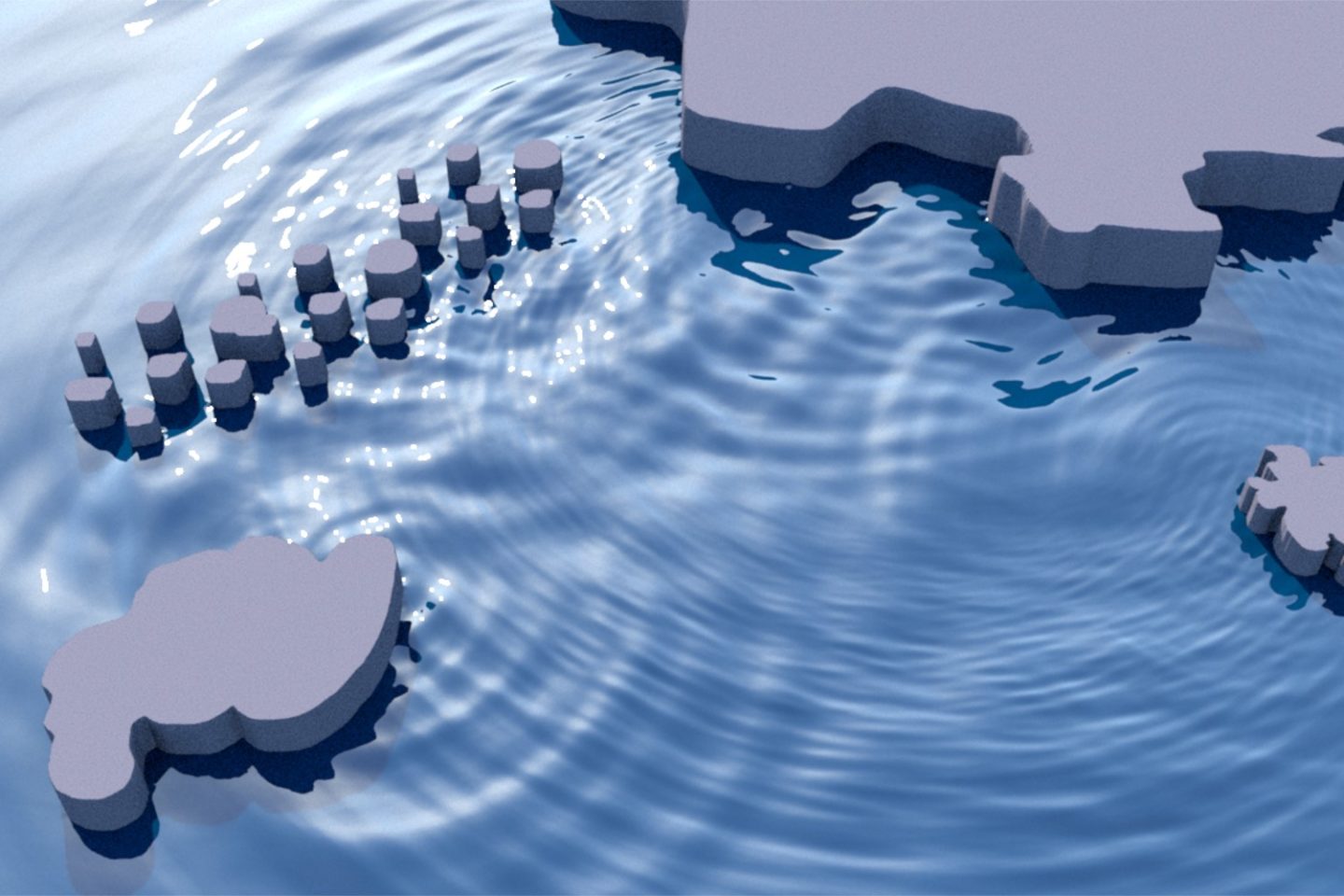

New approach to making realistic water wave animations

In the world of computer graphics modelling, realistic water waves are notoriously difficult and often come at a significant computational expense. This problem is one of the main focus areas of the Wojtan group whose most recent scientific paper details a new method that makes realistic water wave animations more efficient. Lead author Camille Schreck will present the paper (published in ‘ACM – Transactions on Graphics’) alongside Professor Chris Wojtan. Both academics will be focusing on the technical feasibility of the method as well as its more practical applications that could be used to benefit the video game and film industry.

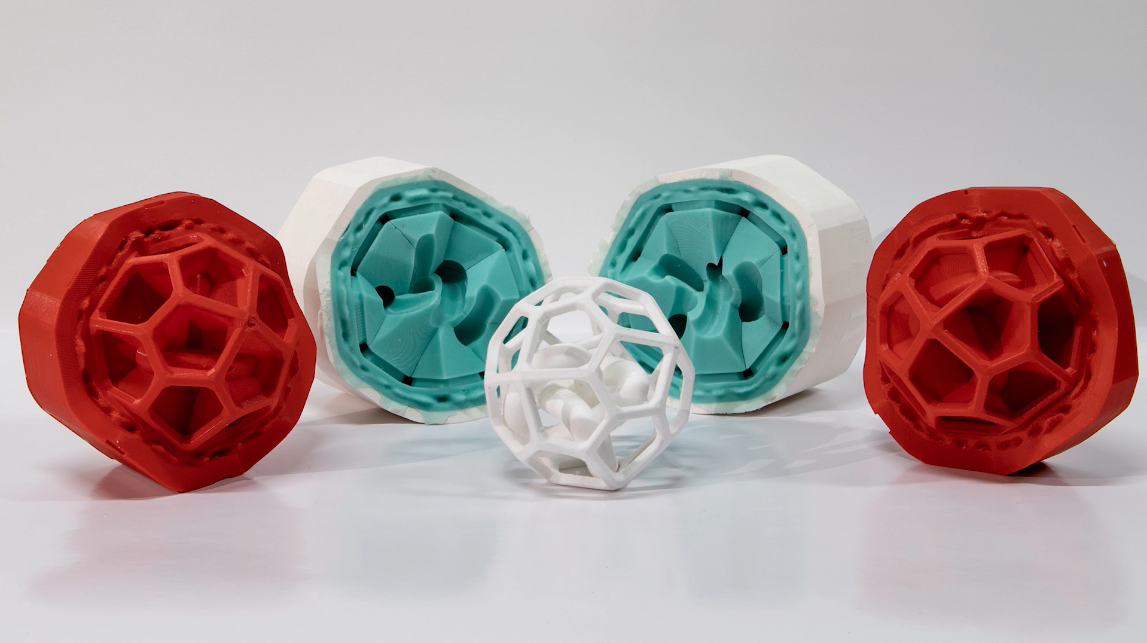

Modernizing silicone molds and casts using 3D printers

Professor Bernd Bickel along with fellow collaborators from the University of Technology Sydney, Institute of Information Science and Technologies Italy (ISTI-CNR Italy) and University of Pisa have developed a special type of 3D printing technique that allows for the automatic design of molds to cast highly complex shapes. Previously, this type of design process involved mostly manual labor and was very costly from a time point of view. The paper – which also has a registered patent – describes an innovative technique that models the fluid escape paths within the mold and also the volumetric decomposition when the silicone fills the mold. This process results in a mold that is able to accurately cast complex objects such as faces, statues and complex geometric circles. The method is not only limited to silicates, but can also be used to produce complex metal objects (pictured below).